Pressure vessels, heat exchanger, reactor, column, Storage Tanks & Tank

farm, Boiler & Boiler Components etc. are considered as static equipment’s.

Major stages of inspection covered for static equipment’s are Approval of Design, drawing &

QAP / ITP; WPS/PQR & Welder Qualifications, raw material identification, long seam fit up,

cirseam fit up, pipe to flange / fittings fit up, nozzle fit up on shell / dished end, NDT witness,

Final Dimensions, Heat Treatment, Pressure Test & Quality documentation.

Pumps, Fans, Agitators, Compressor, Turbines, Screw Conveyors, Motor

and Generator are considered to be part of rotating equipment’s.

General inspection stages followed are raw material identification, NDT of major components,

balancing of blades, rotors etc., Assembling & final dimensions, Performance Test &

documentation.

AIPL Inspection team is fully conversant with the requirements of rotary equipment’s to meet

the code, data sheet & client requirements as completed 1Lakh+ equipment’s since its

inception.

Cranes, hoists, conveyors, escalators etc. & Misc. Components like Valves, pipe & fittings, flanges, LR bends, line pipe & pipeline etc.

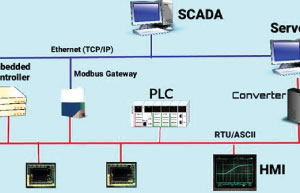

Gauges, Transmitters, JB’s, SCADA, Cables etc.

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. In Pressure Vessel manufacturing & inspection, general components are termed as “Shell, Dished End, Nozzle, Saddle or skirt support, Blind Flanges, Fasteners etc.” PV’s are considered to be of critical nature equipment of any project hence stage inspections are carried out as per applicable code of construction (ASME SEC.VIII Div.1, 2 & 3; BS5500; IS2825; Admerkblatter are few examples of Codes used generally all over world).

A heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. There are various types of Heat Exchangers manufactured based on end application & design requirements. Presently exotic material used HE’s are challenging for manufacturing & inspection where Adiveritas Inspection has a unique expertise as thousands of HE’s inspected & certified since last few years.

Reactor is critical equipment used for complex operations of mixing in pharma, chemical, Oil & Gas, Fertilizer industrial sectors. In addition to pressure vessel component there are rotating parts like agitator, motor, gear box which are essential & required critical inspection stages before installation or final inspection.

A distillation column is an essential item used in the distillation of liquid mixtures to separate the mixture into its component parts, or fractions, based on the differences in volatilities. Fractionating columns are used in small scale laboratory distillations as well as large scale industrial distillations. There are many types of distillation columns, each designed to perform specific types of separations, and each design differs in terms of complexity. Inspection of columns is highly skilled job as it involve not only routine inspection stages but crucial stages like TSR (Tray Support Ring), Baffle, Baskets inspection where measurements are in microns expected & to maintain micron tolerance is challenging task in fabrication equipment’s. We are happy to inform that our AIPL Inspection Experts are fully familiar with all such crucial inspection aspects by conducting multi inspection at fabrication shop as well as construction sites.

An oil depot (sometimes called a tank farm, installation or oil terminal) is an

industrial facility for the storage of oil and/or petrochemical products and from which these products

are usually transported to end users or further storage facilities. An oil depot typically has tankage,

either above ground or below ground, and gantries (framework) for the discharge of products into road

tankers or other vehicles (such as barges) or pipelines.

Pleased to inform that AIPL completed inspection of more than 1000 Nos. Oil Storage tanks for various

Indian refineries like HPCL, IOCL & BPCL in all over India basis.

A boiler is a closed vessel in which fluid (generally water) is heated. The

fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes

or heating applications, including water heating, central heating, boiler-based power generation,

cooking, and sanitation.

AIPL Inspection Experts completed numerous boilers & boiler components inspection & testing

assignments for its various national & international clients at manufacturing shops as well as at

construction sites during & after commissioning as part of project execution.

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action. Pumps operate by some mechanism (typically reciprocating or rotary), and consume energy to perform mechanical work moving the fluid. Pumps operate via many energy sources, including manual operation, electricity, engines, or wind power, come in many sizes, from microscopic for use in medical applications to large industrial pumps.

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor.

A turbine is a turbo machine with at least one moving part called a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades so that they move and impart rotational energy to the rotor. Early turbine examples are windmills and waterwheels.

A screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a "flighting", usually within a tube, to move liquid or granular materials. They are used in many bulk handling industries. Screw conveyors in modern industry are often used horizontally or at a slight incline as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat and bone meal, municipal solid waste, and many others. The first type of screw conveyor was the Archimedes' screw, used since ancient times to pump irrigation water.

An electric motor is a device used to convert electricity into mechanical energy—opposite to an electric generator. They operate using principles of electromagnetism, which shows that a force is applied when an electric current is present in a magnetic field.

In electricity generation, a generator is a device that converts motive power (mechanical energy) into electrical power for use in an external circuit. Sources of mechanical energy include steam turbines, gas turbines, water turbines, internal combustion engines, wind turbines and even hand cranks

A crane is a type of machine, generally equipped with a hoist rope, wire ropes or chains, and sheaves, that can be used both to lift and lower materials and to move them horizontally. It is mainly used for lifting heavy things and transporting them to other places. The device uses one or more simple machines to create mechanical advantage and thus move loads beyond the normal capability of a human. Cranes are commonly employed in the transport industry for the loading and unloading of freight, in the construction industry for the movement of materials, and in the manufacturing industry for the assembling of heavy equipment.

A hoist is a device used for lifting or lowering a load by means of a drum or lift-wheel around which rope or chain wraps. It may be manually operated, electrically or pneumatically driven and may use chain, fiber or wire rope as its lifting medium. The most familiar form is an elevator, the car of which is raised and lowered by a hoist mechanism

Conveyor Systems are mechanical devices or assemblies that transport material with minimal effort. While there are many different kinds of conveyor systems, they usually consist of a frame that supports either rollers, wheels, or a belt, upon which materials move from one place to another.

An escalator is a moving staircase which carries people between floors of a building. It consists of a motor-driven chain of individually linked steps on a track which cycle on a pair of tracks which keep them horizontal.

AIPL got its expertise in inspection & testing of misc. components used in all sectors by handling numerous assignments for various clients nationally & internationally.

Wire gauge is a measurement of wire diameter. This determines the amount of electric current a wire can safely carry, as well as its electrical resistance and weight.

A transmitter is an electronic device used in telecommunications to produce radio waves in order to transmit or send data with the aid of an antenna. The transmitter is able to generate a radio frequency alternating current that is then applied to the antenna, which, in turn, radiates this as radio waves.